Bending machines have been widely used in various industries for many years, especially in the metalworking and woodworking industries. These machines operate by applying pressure to a metal or wooden part, transforming its shape and producing desired bends. The most common types of bending machines are tube and pipe benders, press brakes, bar benders, and plate bending rolls.

In this article, we will discuss everything you need to know about bar bending machines, their types, features, and benefits.

What is a Bar Bending Machine?

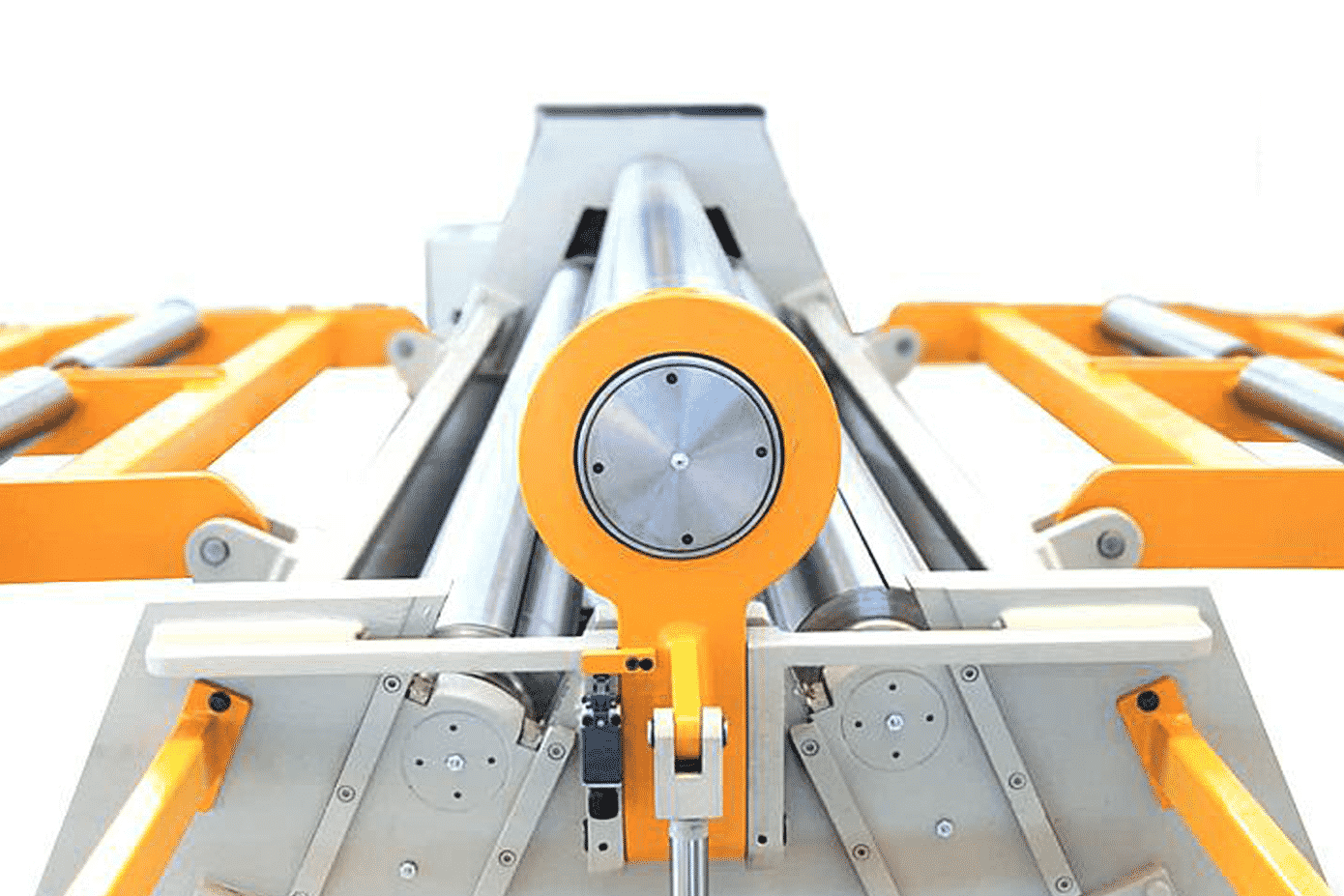

A bar bending machine is a tool used for bending steel bars, rods, and solid rebar. This machine is primarily used in construction projects where the steel bars need to be bent into specific shapes and angles to form a reinforced structure. These machines are widely used in civil engineering, reinforcing steel processing plants, and real estate construction industries.

Types of Bar Bending Machines

1. Manual Bar Bending Machines

These machines are operated manually and are suitable for small-scale construction projects. Manual bar bending machines come in a compact size and can be easily transported to the worksite. They are easy to use and require minimal maintenance.

2. Automatic Bar Bending Machines

These machines are fully automated and perform multiple functions, including cutting, bending, and feeding the steel bars. They come with a digital display panel, making it easy to operate and monitor the bending process. They are highly efficient and can handle high-volume production.

Benefits of Bar Bending Machines

1. Accuracy

Bar bending machines ensure high accuracy and precision in the production process. These machines can bend steel bars into different shapes and angles with ease, ensuring that the final product is of the desired shape and size.

2. Time-Saving

Using a bar bending machine can help reduce the time and effort required to bend steel bars. These machines can bend steel bars quickly and efficiently, saving you valuable time and increasing your productivity.

3. Durability

Bar bending machines are designed to last long and can withstand harsh working conditions. They are made of high-quality materials that can withstand the wear and tear of consistent use.

4. Cost-Effective

Investing in a bar bending machine can save you a lot of money in the long run. You can cut down labor costs by using these machines and increase your profits by providing high-quality products to your clients.

Conclusion

Bar bending machines are an essential tool in the construction industry. They are highly efficient, accurate, and cost-effective, making them a must-have in any construction project. Whether you choose a manual or automatic bar bending machine, you can be sure that you are making a wise investment that will pay off in the long run. With the right machine, you can increase your productivity, reduce labor costs, and provide high-quality products to your clients.